Issue #2:

SPLH Is Not a Target

Last week, I said labor % is lying to you.

This week I’ll go one step further:

SPLH is not a target.

And the operators who treat it like one end up cutting the very labor they need to grow revenue.

Let me explain.

Most franchisees, including ourselves, have targets of $85- $100 sales per labor hour depending on the store. But to say that is the target is really a misnomer,because if you try to hit that number every hour of the day, you will never get there. It’s not realistic.

You can’t open with one person.

You can’t close with one person.

You can’t schedule below minimum required labor.

There are hours in every store that are mathematically impossible to optimize.

And pretending otherwise leads to bad decisions, which is why we use the term:

V-SPLH: Volume Sales Per Labor Hour.

The V matters.

This is the number you should hit when you are at volume.

When the store is actually busy and you have the opportunity to produce.

Not during dead hours.

Not during minimum staffing.

Here’s where operators get it backwards.

They look at a daily SPLH number.

They don’t hit it. so they cut labor during peak hours to make up for slow times.

Which is insane.

Because now you’re under-staffed when customers are there.

You’re missing sales when volume exists which only protects a metric instead of protecting revenue.

The only way to artificially hit a daily SPLH number is by cutting people when you need them most. That is also the fastest way to stall growth.

Let me give you a real example.

If your minimum required labor is two people and you’re only going to do $150 that hour; you will not hit an $85 SPLH target.

It’s out of your control.

But if you’re going to do $300 that hour?

Now you justify the third person and the math works applying V-SPLH.

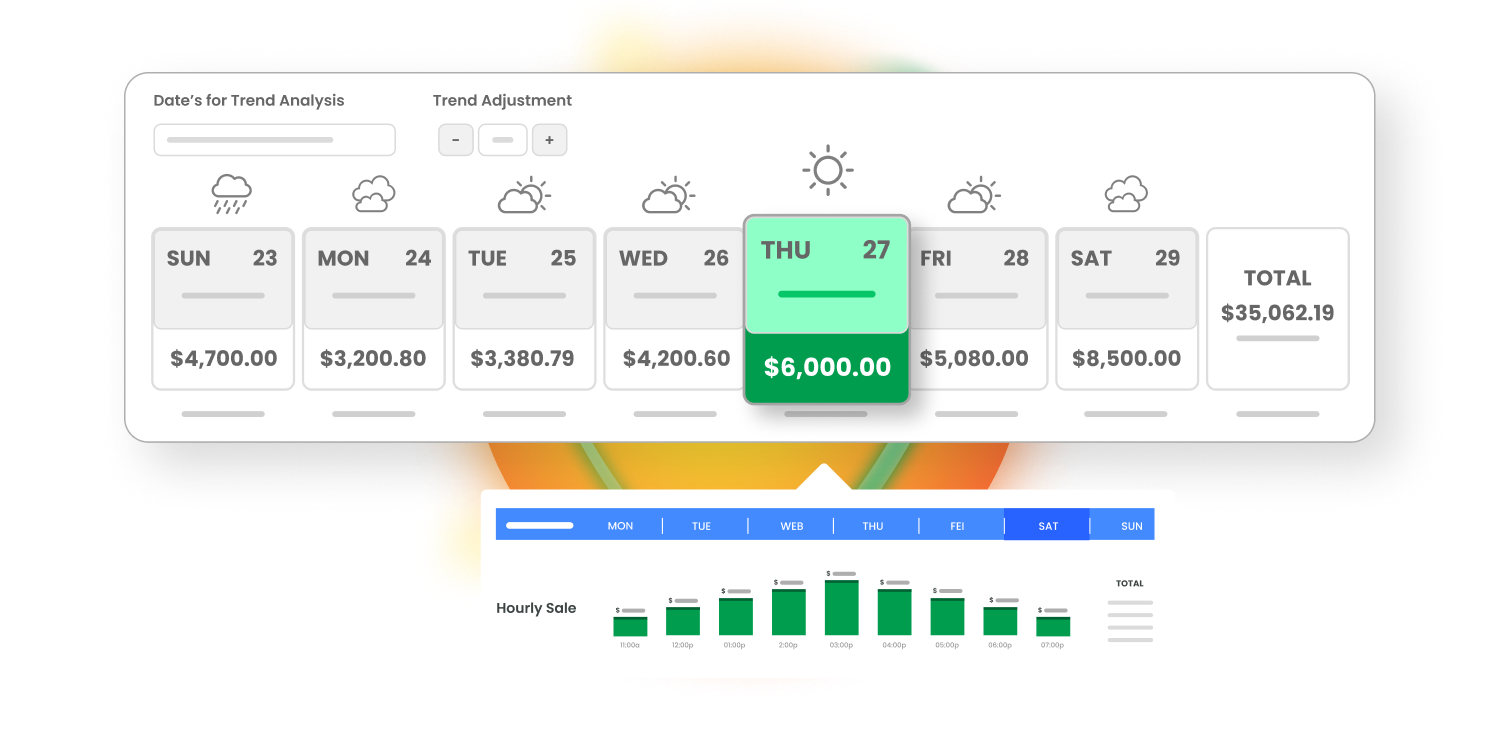

When we do our scheduling, we have a gray line that indicates pushing required labor up to service the sales volume hour by hour. Not all hours are equal and busy hours justify labor; slow hours don’t. It sounds simple and it is but putting it into practice across multiple locations, for every hour of every day is not simple. Understandably operators (managers) are busy so the default is to just throw people on the schedule according to store hours and when the people are available, resulting in hundreds of dollars per day per location in wasted labor hours. Also known as wasting profit.

There’s another layer most operators miss.

The more employees you add, the tighter your V-SPLH should get.

Employee five and six are incrementally less productive than one and two.

There’s a point of diminishing returns.

Which means V-SPLH should move with volume and should adjust by weekend, by season and by store.

It’s never static and it’s always contextual and you should be calculating this for every shift, every week, every time you create a schedule.

It’s critical that your calculations are built like this:

SPLH is a derivative of volume and minimum required labor versus a fixed scoreboard you chase blindly.

Operators don’t go bankrupt because sales are down. They go bankrupt because sales are up 15% with profit leaking out the back door unknowingly.

Operators schedule five people when three would do.

They refuse to incentivize the behavior that drives upsells and add-ons, leaving revenue (profit!) on the table.These operators spend time chasing metrics without understanding them.

SPLH doesn’t create profit. The behavior of the team members during volume does.

Next week, we’ll talk about the behavior lever that most directly drives V-SPLH upward and why cutting costs almost never fixes a revenue problem.

Until next week, remember:

Don’t protect the metric.

Protect the volume.

This is part two of the playbook. And profit only comes when the pieces work together.

Subscribe and follow along for the next 8 weeks as I share how it all fits together.

.jpg)